Vacuum Casting

Vacuum casting is a manufacturing process that enables the production of high-precision parts using rapid molds It involves creating a mold or model through additive manufacturing, into which liquid resins are poured under vacuum to eliminate air bubbles and ensure uniform material distribution

This method is ideal for creating functional prototypes, short production runs, and customized components, offering a fast and cost-effective solution with high-quality finishes. Depending on the material used, rigid parts with properties similar to industrial thermoplastics, flexible parts in elastomers or coatings with specific technical characteristics can be obtained.

At Nort3D, we have experience in vacuum casting to offer solutions adapted to the needs of each sector, ensuring precision, repeatability and materials with optimized properties for each application.

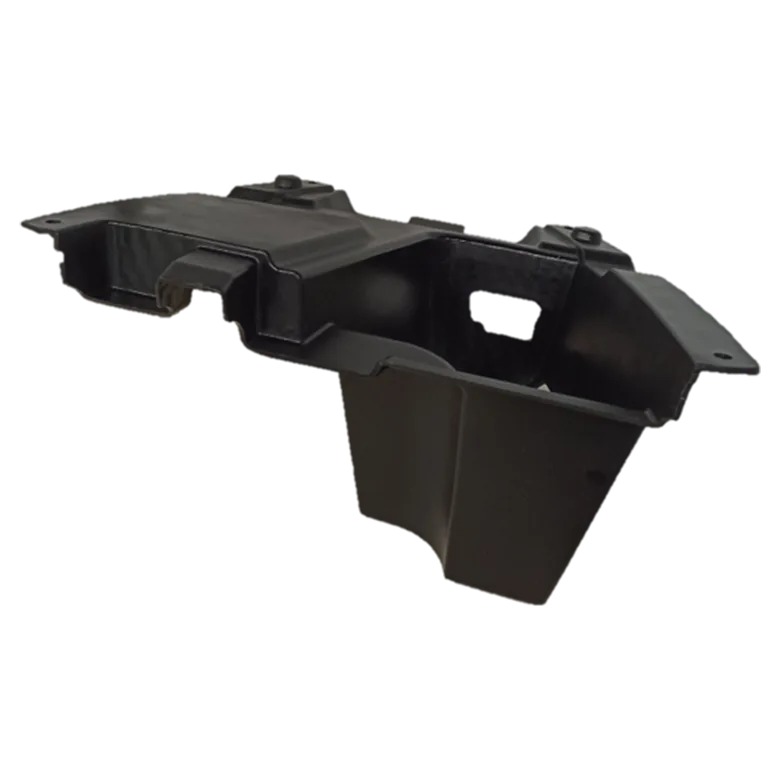

Rigid Parts

Vacuum casting with rigid resins allows for the production of parts with excellent mechanical properties and high-quality finishes, simulating materials such as ABS, PC, or PP. This process is ideal for functional prototypes, short production runs, and parts with specific requirements.

At Nort3D, we use technical materials that replicate the characteristics of industrial polymers, ensuring parts with high dimensional stability and structural resistance. To achieve this, a master model must be manufactured using additive manufacturing, which will then be used to create the silicone mold for final part reproduction.

Success stories

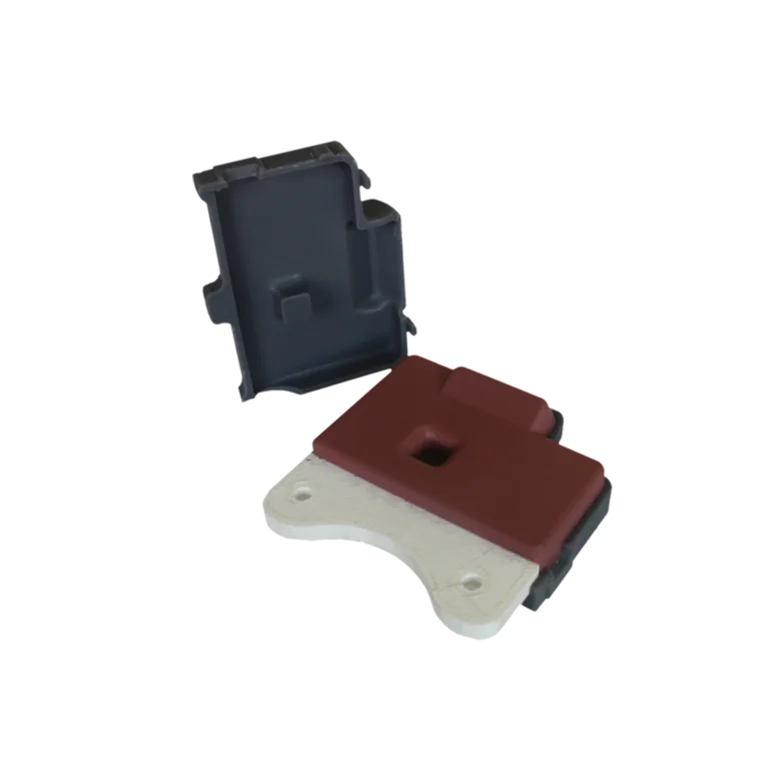

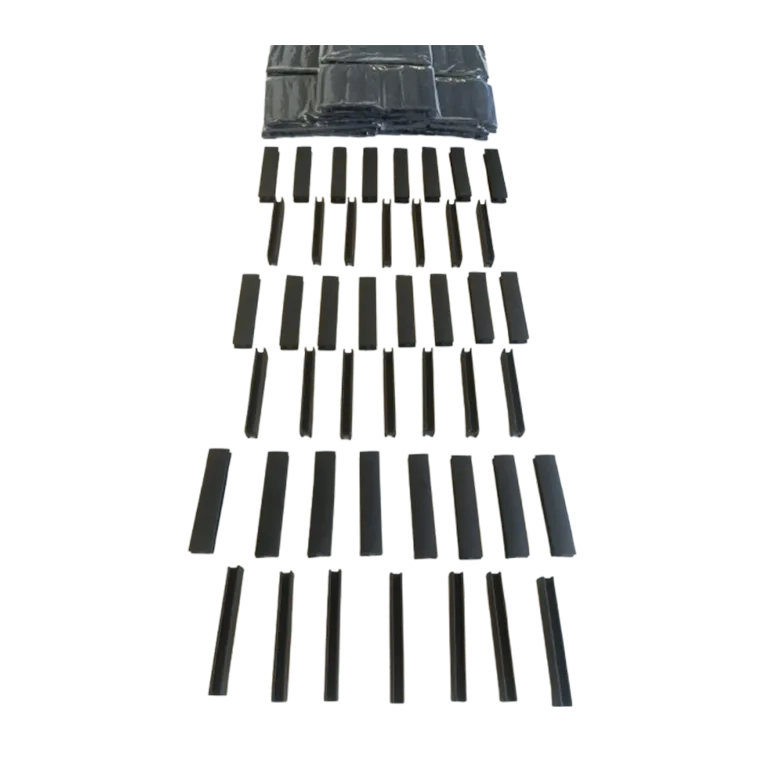

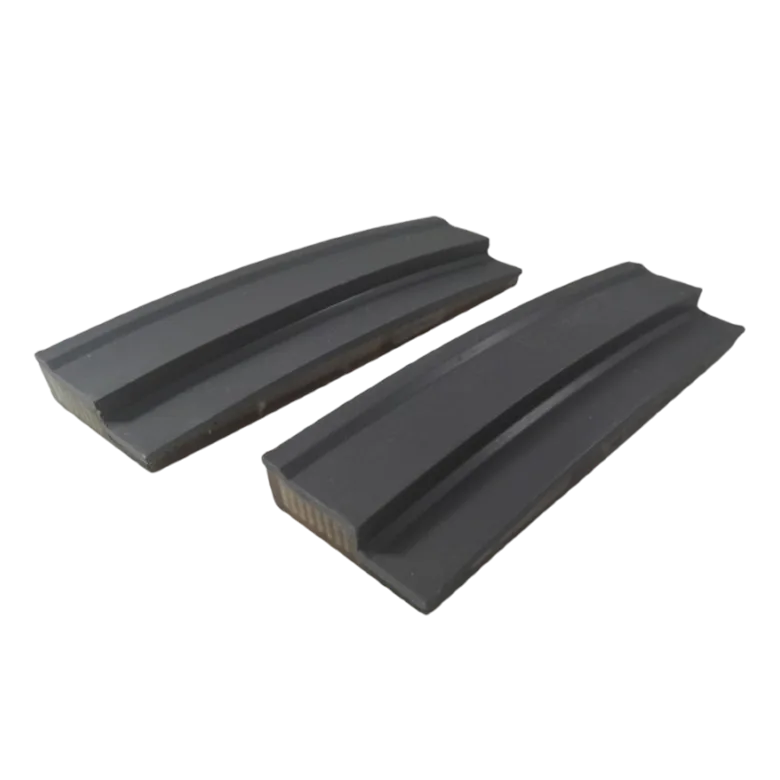

Rubber Parts

We offer the production of flexible elastomer parts using vacuum casting, obtaining components with different Shore hardness levels and mechanical behavior tailored to each application. Common applications include custom seals and gaskets, impact and vibration-absorbing parts, and aesthetic and functional flexible parts for machinery or final products.

We provide a wide range of polyurethane resins with specific chemical, thermal, and mechanical resistance properties, ensuring durable and functional rubber parts.

Success stories

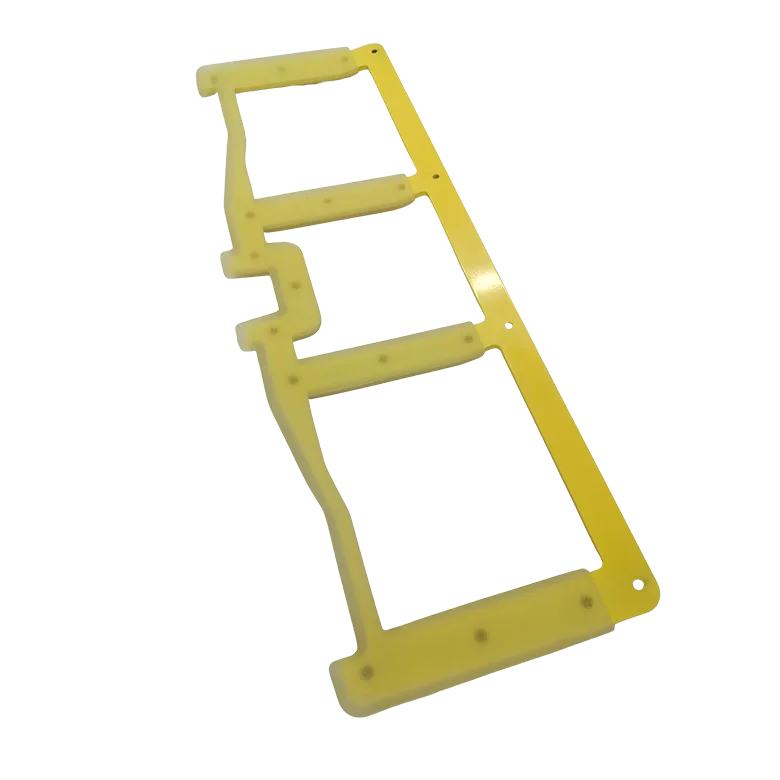

Coatings

The vacuum casting process is also used for manufacturing technical coatings, applicable to sectors such as electronics, automotive, and consumer goods. Thanks to this method, it is possible to achieve durable protection for electronic or mechanical components, ergonomic and aesthetic coatings for housings and tools, and coverings with mechanical or chemical properties tailored to specific needs.

By selecting specific materials, we optimize the functionality of the coating and ensure a high-quality finish.