INDUSTRIAL 3D PRINTERS FOR MASS PRODUCTION IN RESIN

Photocentric is a pioneer in high-precision 3D printers based on LCD technology for the mass production of large and complex parts. With market-leading build volumes, these printers are designed to manufacture everything from detailed prototypes to functional parts across a variety of industrial applications.

Photocentric's advanced technology accelerates production times, enabling companies to bring products to market quickly and efficiently.

LC Magna

The LC Magna is a high-performance industrial 3D printer designed by Photocentric to produce large parts or massive volumes with precision and speed. With its extensive print area and advanced photopolymerisation technology, the LC Magna is ideal for companies looking to take additive manufacturing to an efficient production scale.

Key features:

- High production capacity: The LC Magna features a print area of 510 x 280 x 350 mm, allowing for the creation of large pieces or multiple components in a single print cycle.

- Precision and detail: With a resolution of 137 microns on the XY axis, the LC Magna delivers superior print quality, ideal for applications in dentistry, automotive, jewellery, and more.

- Optimised printing speed: Its ability to print layers in just 6-8 seconds ensures fast production cycles, making it a cost-effective option for mass manufacturing.

- Compatibility with a wide range of resins: Designed to work with various Photocentric resins, the LC Magna can adapt to multiple applications, from prototypes to final functional parts with specific features.

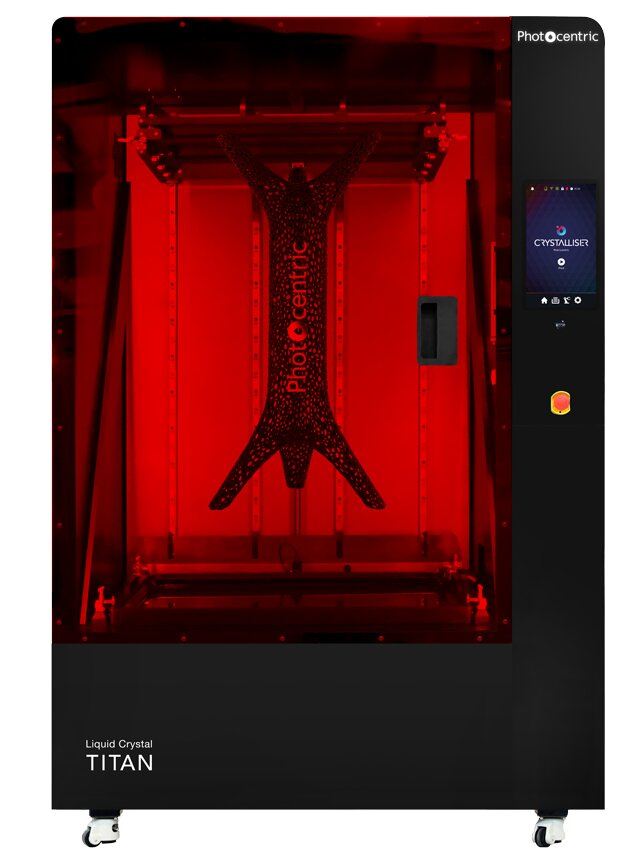

LC Titan

The LC Titan is Photocentric's largest format 3D printer, designed for the mass production of large, high-precision parts. With an unprecedented print volume, this printer enables companies to scale additive manufacturing to new levels, optimising productivity and reducing costs.

Key features:

- Industry-leading print volume: With a capacity of 695 x 385 x 1200 mm, the LC Titan is ideal for large parts and mass production, offering versatility for multiple industrial sectors.

- High precision and quality: With a resolution of 91 microns on the XY axis, it ensures detailed finishes and high-quality surfaces, essential for demanding applications.

- Fast and efficient printing: Capable of printing at 86 mm/h with layer thicknesses of 350 μm, the LC Titan enables agile production cycles to optimise manufacturing time.

- Compatibility with a wide range of resins: Validated for Photocentric and BASF resins, it offers flexibility for applications ranging from prototypes to functional end-use parts.

The LC Titan redefines the boundaries of industrial 3D printing, providing a robust and efficient solution for companies seeking maximum production capacity and quality in every print. The NILS 480 is ready for Industry 4.0, facilitating its integration into advanced production systems. Additionally, it features an