Advanced 3D Scanning Solutions

At Nort3D, we offer advanced industrial 3D scanning solutions using state-of-the-art technology to achieve precise measurements in dimensional metrology, quality control, reverse engineering, and digitization of complex parts. Our specialized team and the latest generation of 3D scanners enable us to accurately capture the geometry of any object—from small components to large structures. Additionally, we enhance our service value through:

High-Precision 3D Coordinate Measurement (CMM)

3D coordinate measuring machines (CMM) are essential for ensuring quality and precision in the industry. In our laboratories, LK measuring machines excel in sectors such as automotive, aerospace, and mechanical. Thanks to their ceramic construction, these CMMs deliver extremely precise and stable measurements while meeting strict geometric tolerances and standards. They incorporate various technologies:

Point-to-Point Contact

We use point-to-point contact measurement probes, ideal for GD&T (Geometric Dimensioning and Tolerancing) evaluations. This technology, recognized for its high accuracy and repeatability, ensures that each component meets the required specifications.

Continuous Contact

Las sondas de contacto continuo capturan cientos de puntos por segundo, ofreciendo una visión detallada de la superficie inspeccionada. Esto permite detectar variaciones mínimas y realizar evaluaciones precisas, optimizando los procesos de fabricación y asegurando la calidad en cada etapa.

Laser Scanning

Laser scanning in CMM enables detailed analysis of deviations, facilitating quick decisions and the implementation of corrective measures. This technology captures large volumes of data in less time, reduces correction times and enables CAD-based off-line programming, without the need for the physical part. In addition, non-contact measurement ensures accuracy on any material, with no risk of deformation.

Portable 3D Scanning

We offer portable 3D scanning solutions that capture the geometry of parts and structures with high precision and speed, both at our facilities and on-site. These technologies are suitable for components of all sizes, facilitating data integration into digital models and optimizing production processes.

Digitalización 3D Portátil con Brazo de Medición

The MCAx S+ portable measuring arm and Nikon ModelMaker H120 Laser Scanner offer high productivity and metrological accuracy. They work effectively in both contact and non-contact measurements, enabling agile freeform and dimensional analysis on parts of any size. They are ideal for industries such as automotive, aerospace and energy, and are used in the inspection of tools, dies, car bodies, rolled parts, injected components and 3D printed products.

Portable 3D Scanning with Scantech

Our portable 3D scanning solution with Scantech combines high accuracy and versatility to accommodate all types of measurements, from large parts to small components, in both confined spaces and large environments. Thanks to its advanced, completely wireless technology, it allows you to capture high-density metrology data with complete freedom of movement, either at our facilities or directly on site. This comprehensive solution facilitates the creation of accurate digital models, optimizing metrological analysis and enhancing quality control in your production processes.

Computed Tomography (CT) Inspection

We utilize computed tomography (CT) inspection equipment and a team of specialists who provide detailed material analysis, thorough assembly inspections, rigorous quality control, and advanced X-ray metrology, delivering precise information on both the exterior and interior of each part.

Internal inspection with non-destructive testing (NDT)

Non-destructive testing allows internal part inspection without cutting or damaging the object. Using advanced X-ray and computed tomography (CT) technology from Nikon, we deliver precise, contact-free inspections — ideal for high-demand technical components.

Common applications:

- Detection of internal defects, cracks or porosity

- Verification of component placement

- Identification of hidden features

- Analysis of shrinkage and voids

Ensure quality without compromising your parts.

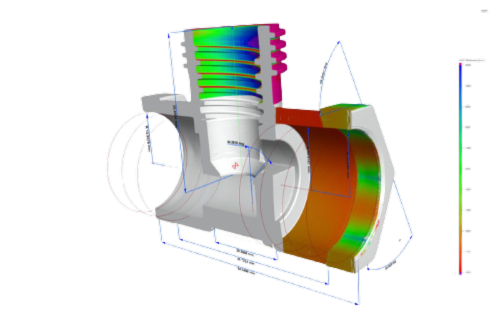

3D metrology with computed tomography

We offer high-precision measurement of internal and external geometries using advanced X-ray computed tomography systems. Our process ensures strict dimensional control and high repeatability — ideal for validating manufacturing processes.

Common applications:

- Measurement of internal channels and hidden cavities

- Wall thickness analysis

- Accuracy verification in 3D prints

- Comparison with the CAD model

Quality assurance with X-ray inspection

Our X-ray inspection services ensure that parts have been correctly manufactured, confirming they perform their function safely and reliably. This non-destructive technique is essential in industries where internal precision and structural integrity are critical.

Key applications include:

- In the aerospace sector, we inspect turbine blades and engine components to ensure internal integrity.

- In medical devices, we validate implantable mechanisms and surgical tools without disassembly.

- In automotive, we detect porosity or cracks in cast parts such as engine blocks or housings.

- In electronics, we verify hidden solder joints in PCBs with BGA or QFN components.

- In the energy sector, we analyze welds in pipelines and critical valves to prevent leaks or structural failure.

- In composites and laminates, we verify the correct fiber alignment and absence of internal voids, ensuring mechanical strength.

With this technology, we meet the most demanding standards — without damaging the inspected parts.

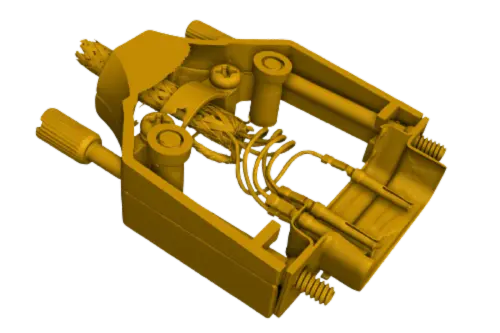

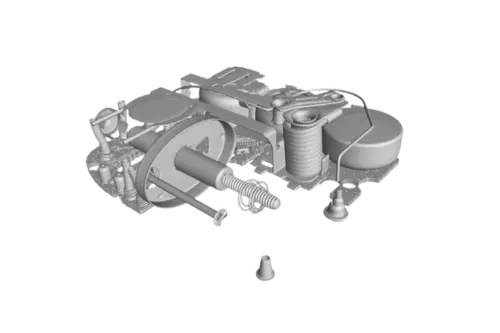

Reverse engineering

3D scanning using computed tomography (CT) captures all the geometric details of a part with high precision — even in internal, hidden or hard-to-reach areas. It is a key tool in reverse engineering, enabling the creation of accurate and complete CAD models from physical samples without disassembly or surface contact.

Typical applications:

- Scanning of technical parts with internal cavities or hidden features

- Inspection of transparent or semi-translucent components (plastics, resins, etc.)

- Generation of high-precision CAD models from very small or detailed parts

- Reconstruction of broken or deformed parts for reproduction or redesign

- Development of custom tooling or adaptation to existing components

Thanks to this technology, it's possible to recover designs without drawings, optimize existing solutions, and accelerate innovation in sectors like medical devices, microelectronics, automotive, and composite materials.

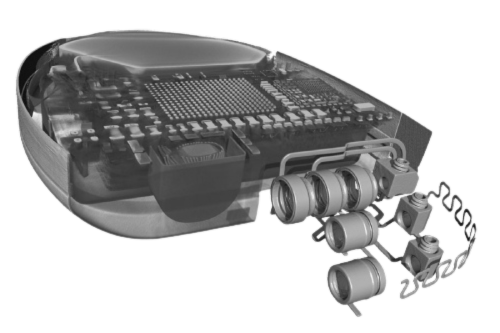

Failure analysis

Disassembling a faulty product may destroy key evidence needed to identify the root cause. With 3D scanning via computed tomography (CT), it’s possible to examine the internal structure of a component without damaging it, enabling faster and more accurate failure analysis.

Typical applications:

- Detection of breaks in wires or internal connections

- Identification of melted or damaged components

- Generation of internal views for technical investigations or legal evidence

- Detection of structural cracks or microfractures

- Verification of missing, misaligned or incorrect assemblies

This technology speeds up diagnostics, improves reliability, and supports informed decision-making.